We are SITRAPLAS

Competence in engineering plastics

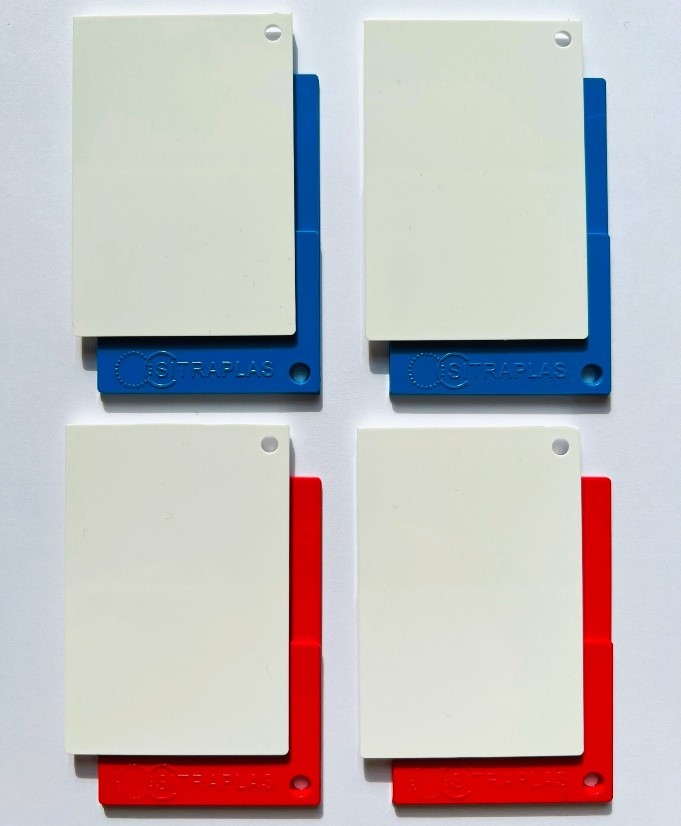

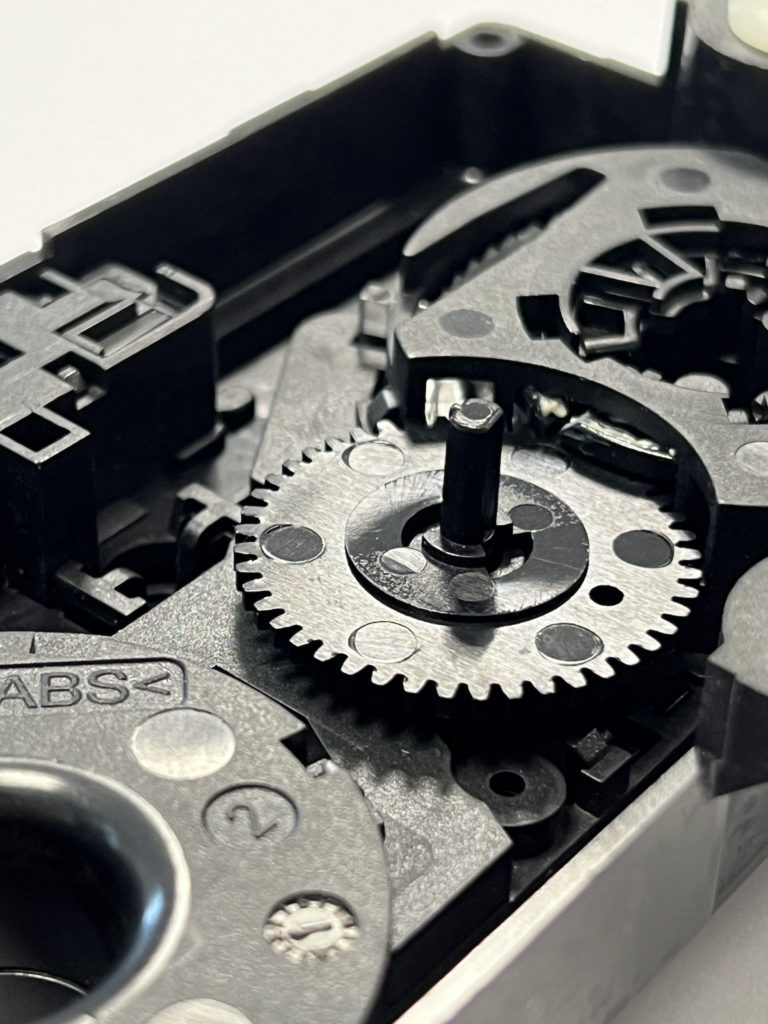

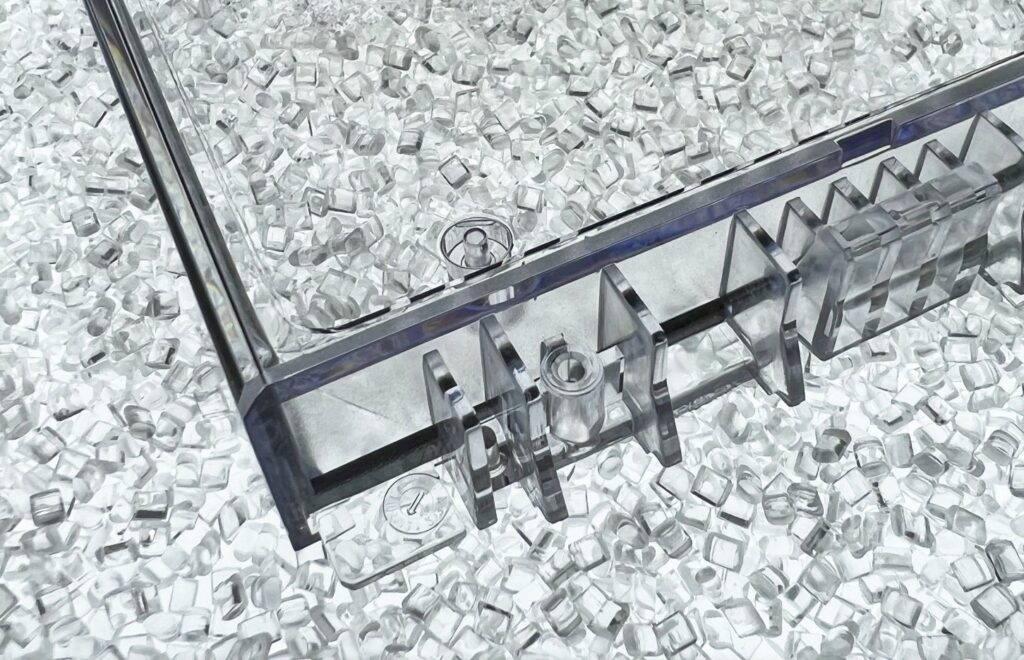

As a production company with innovative product solutions, SITRAPLAS is your industrial partner for individual compounds. At our company headquarters in Bünde, East Westphalia, we develop and manufacture high-performance plastic compounds.

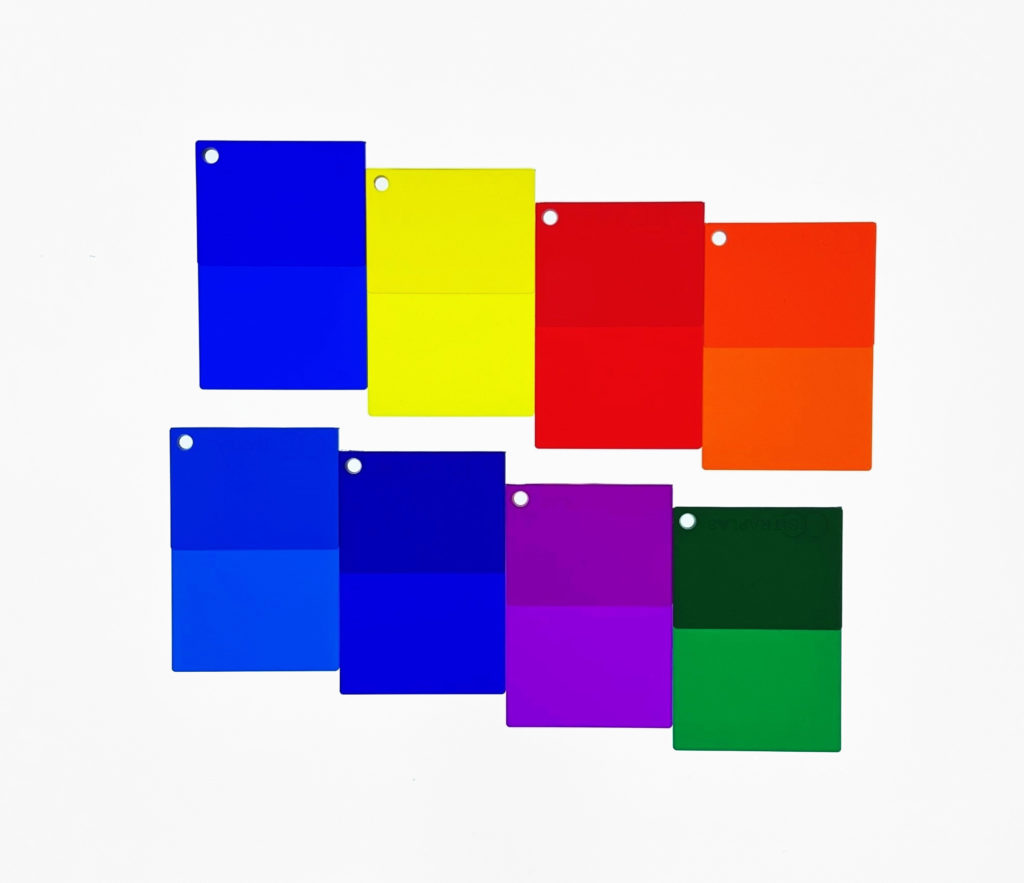

Customers in the automotive, domestic appliance and electrical industries, among others, benefit from our tailor-made solutions worldwide. We offer you high-quality, unique compounds based on various base polymers, such as PC, ABS, ASA, PBT, PMMA and corresponding blends for your technical application.

Our solutions for your market

Find the right product quickly!

Looking for EN-Light, the TF series or Green Compounds? You will find what you are looking for in our product overview.

> 2.500

Recipes

Our developers have done a great job. We can draw on a database of over 2500 recipes. This allows us to offer our customers the best possible solutions cost-efficiently, flexibly and quickly.

> 630

Customers

From consulting at the beginning of the project, the first formulation to production readiness at the customer's site - the highly qualified and experienced SITRAPLAS team is your contact. Our long-term customer relationships from various industries are based on intensive technology partnerships.

> 4.100 t

Capacity

Due to our modular production processes, we supply plastic compounds from very small quantities to large tonnages. We guarantee short delivery times worldwide. Our process monitoring is precise and guarantees the greatest possible batch and quality reliability - even when scaling up to our production facilities.

Sustainability at SITRAPLAS

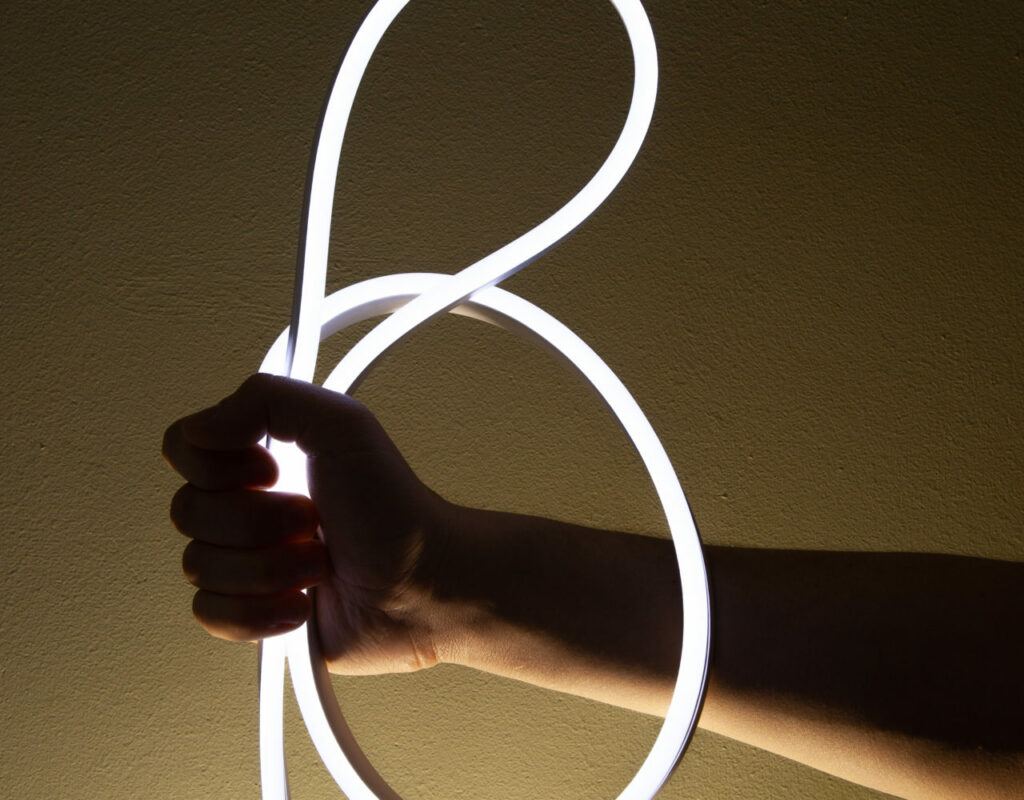

With individual plastic compounds from the GREEN COMPOUNDS series, our customers receive high-quality products made from sustainable or bio-based raw materials. The first-class compounds are used in various sectors: from the automotive industry to the household appliance industry.

Building block for more sustainable compounding

Production waste is an important building block for more sustainable compounding. That is why we collect and sort the waste so that it can then be ground up and used as a valuable raw material for our GREEN COMPOUNDS.

Reuse of 92% of plastic waste

Whether virgin materials or additives, materials from the internal raw material cycle or purchased regrind from post-industrial and post-consumer waste: In our production processes, all of these products undergo close quality controls.

CO2-neutral production

We produce all our compounds using 100% renewable energy and support the EKOenergy label to promote sustainable energy production and international climate and environmental protection projects.

Energy efficiency as a declared goal

Digital and detailed: We monitor the energy consumption of our processes, such as electricity, water and compressed air, on a daily basis so that we can intervene quickly if necessary. With this in mind, our entire compounding process is optimized for energy efficiency. We not only analyze energy consumption very closely. From the screw to the BigBag - here too, we identify sustainable solutions by checking which consumables can be dispensed with or used for longer. Wherever possible, we make processes paperless.

Calculate CO2 footprint

We calculate the CO2 footprint of our plastic compounds during product development. Based on the transparent environmental impact, customers make a well-founded and sustainable choice regarding their own product applications.

2023: GREEN COMPOUNDS saved 5,000 tons of CO2

(Estimate based on the use of secondary raw materials and/or other goods with biogenic components)

News

Company

SITRAPLAS partners with you to produce individual resin compounds for state of the art product solution.